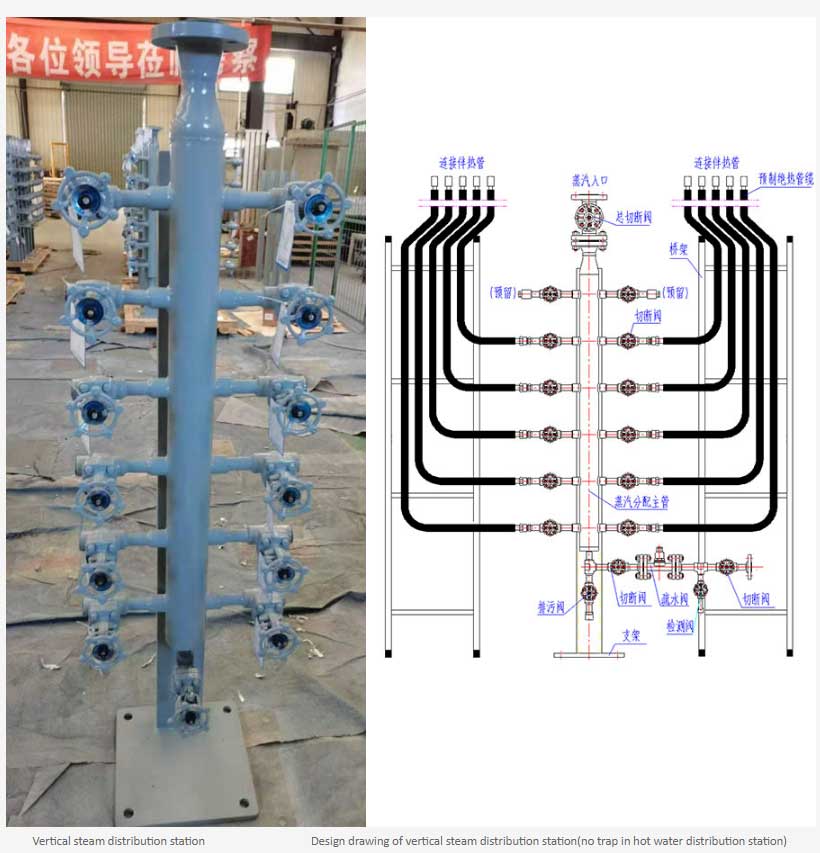

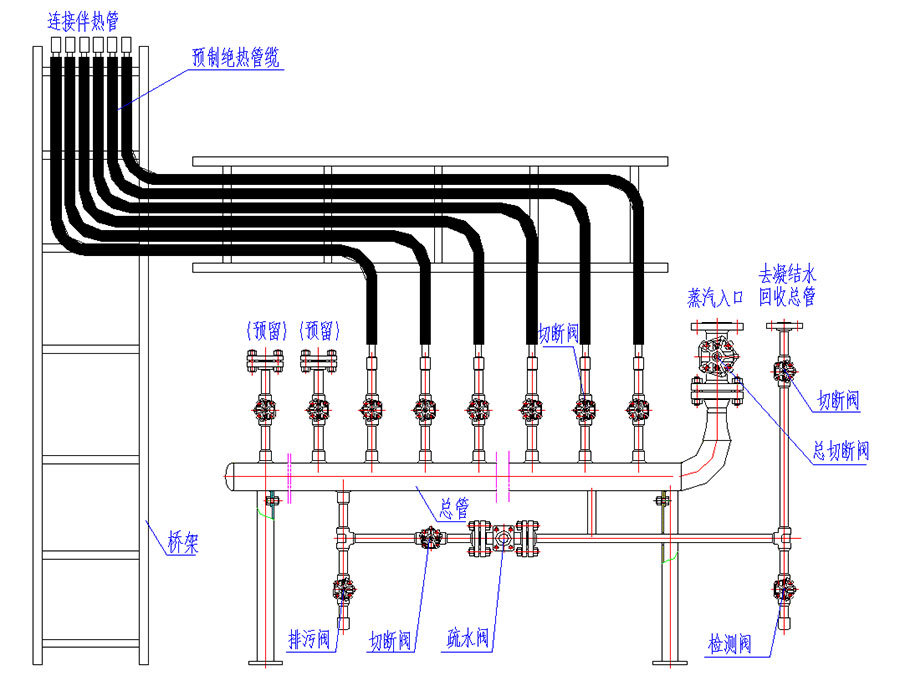

Horizontal steam distribution station

Design drawing of horizontal steam distribution station

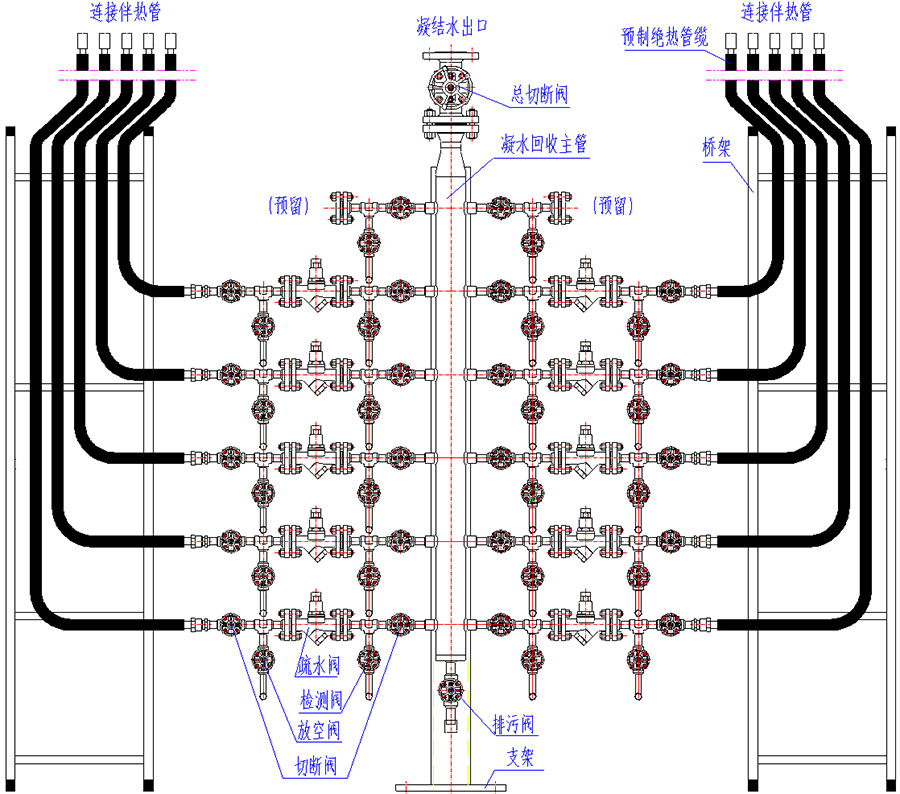

Vertical condensate recycling station

Design drawing of vertical condensate recycling station

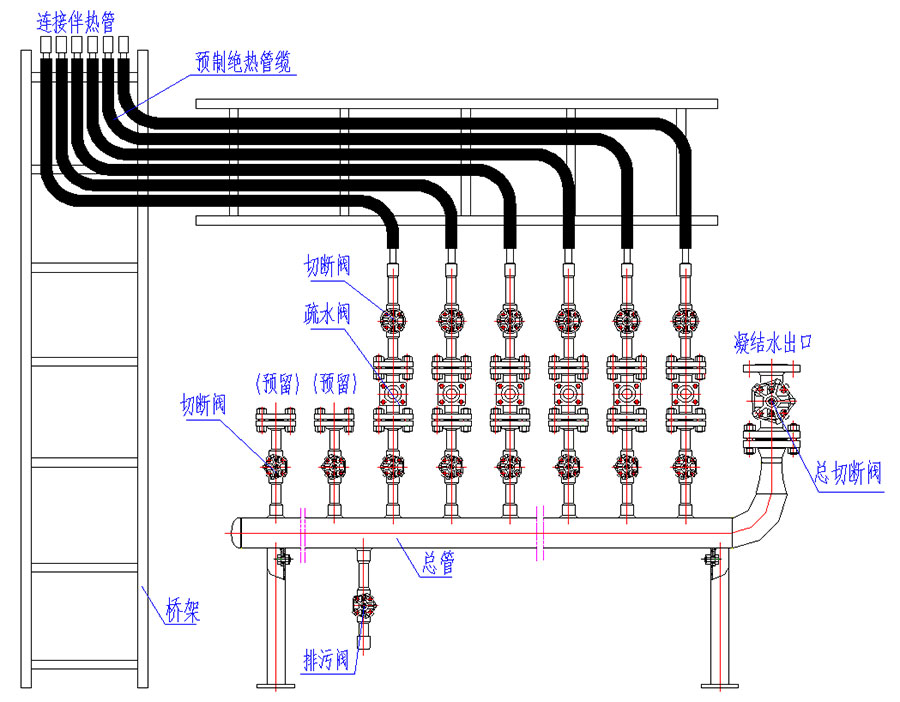

Horizontal condensate recycling station

Design drawing of horizontal condensate recycling station

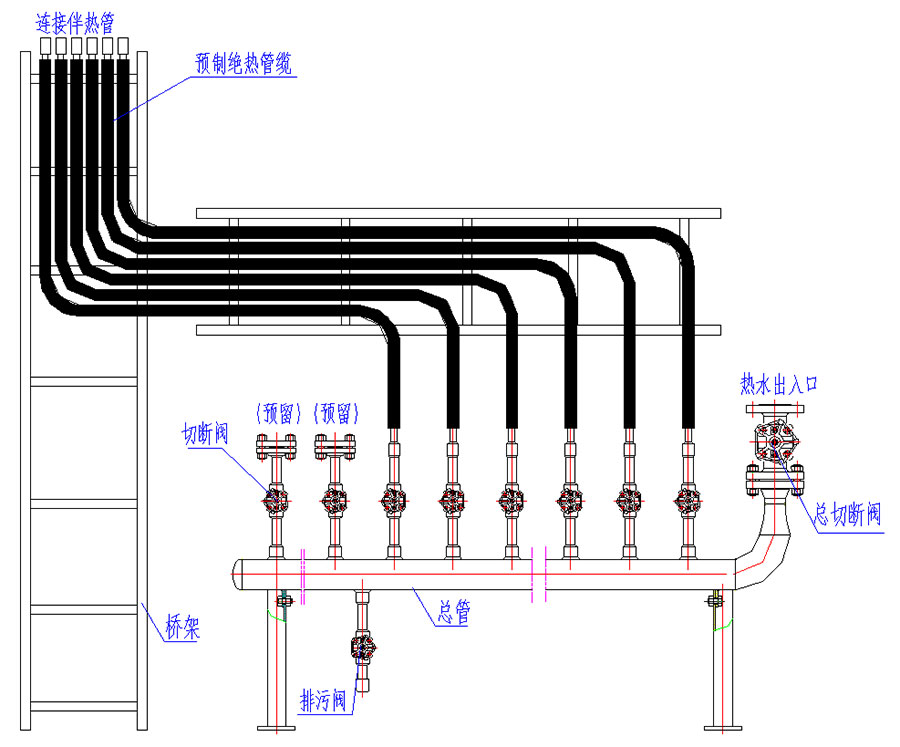

Horizontal hot water distribution station, recycling station

Design drawing of Horizontal hot water distribution station, recycling station

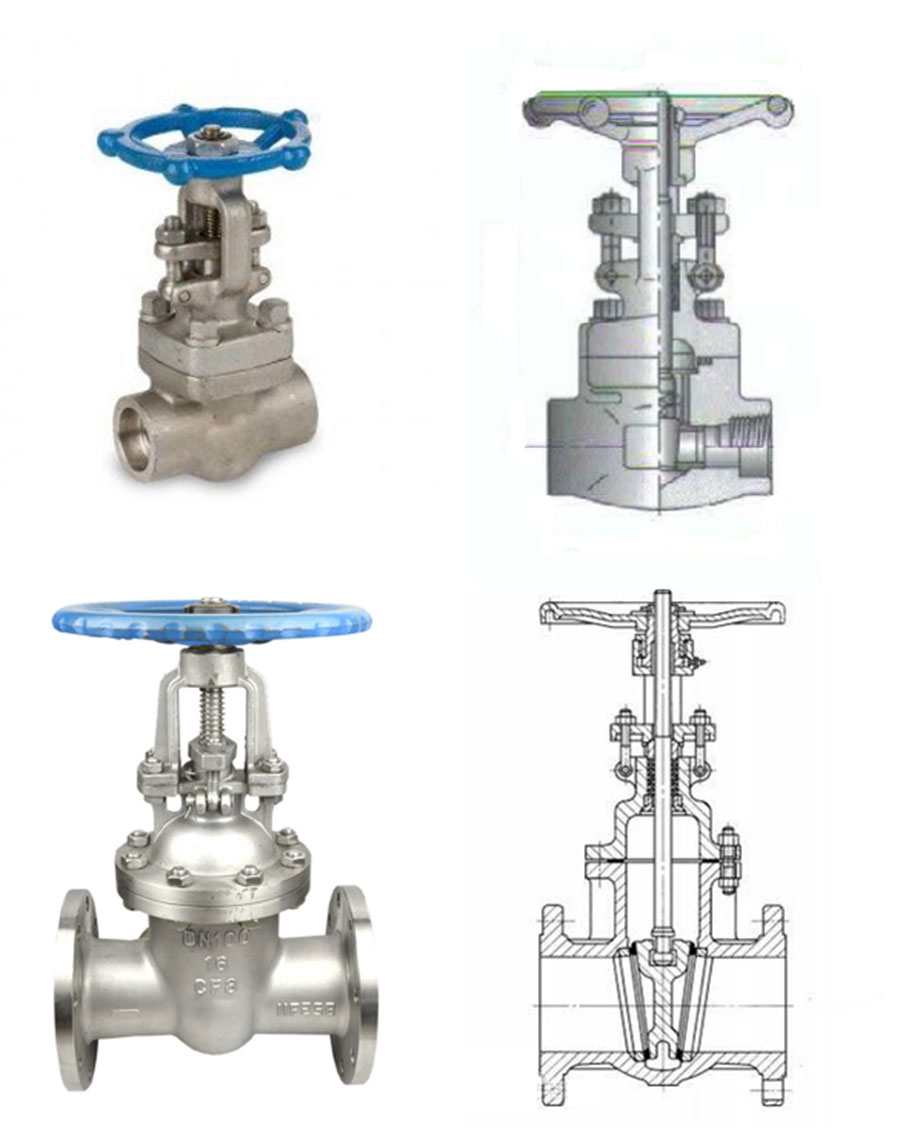

(1)Gate-valve

The cut-off valve used in the old integrated tracing station is the gate valve, which can be made of A105 carbon steel or 304 stainless steel. Connection mode can provide flange connection, socket welding connection, internal thread connection.

Product advantages:

1. The fluid resistance is small, the sealing surface is washed and eroded by the medium, and the sealing performance is good.

2. It is easier to open and close.

3 medium flow is not restricted, does not disturb the flow, does not reduce pressure.

4. Simple shape, short structure, good manufacturing technology, wide range of application.

Inverted bucket trap

Bimetal trap

(2)Trap

The trap, also known as the drainage valve, is to discharge condensate, air and carbon dioxide gas in the steam system as soon as possible, while automatically preventing steam leakage to the maximum extent. There are many kinds of traps, each with different performance. There are mainly mechanical trap, thermostatic trap, thermodynamic trap.

There are two main types of traps used in steam tracing system:

-- inverted bucket type

-- bimetallic type

These two traps have excellent impurity resistance, meet the requirements of horizontal or vertical piping installation, high back pressure, long service life, and are widely used in the heat tracing system.